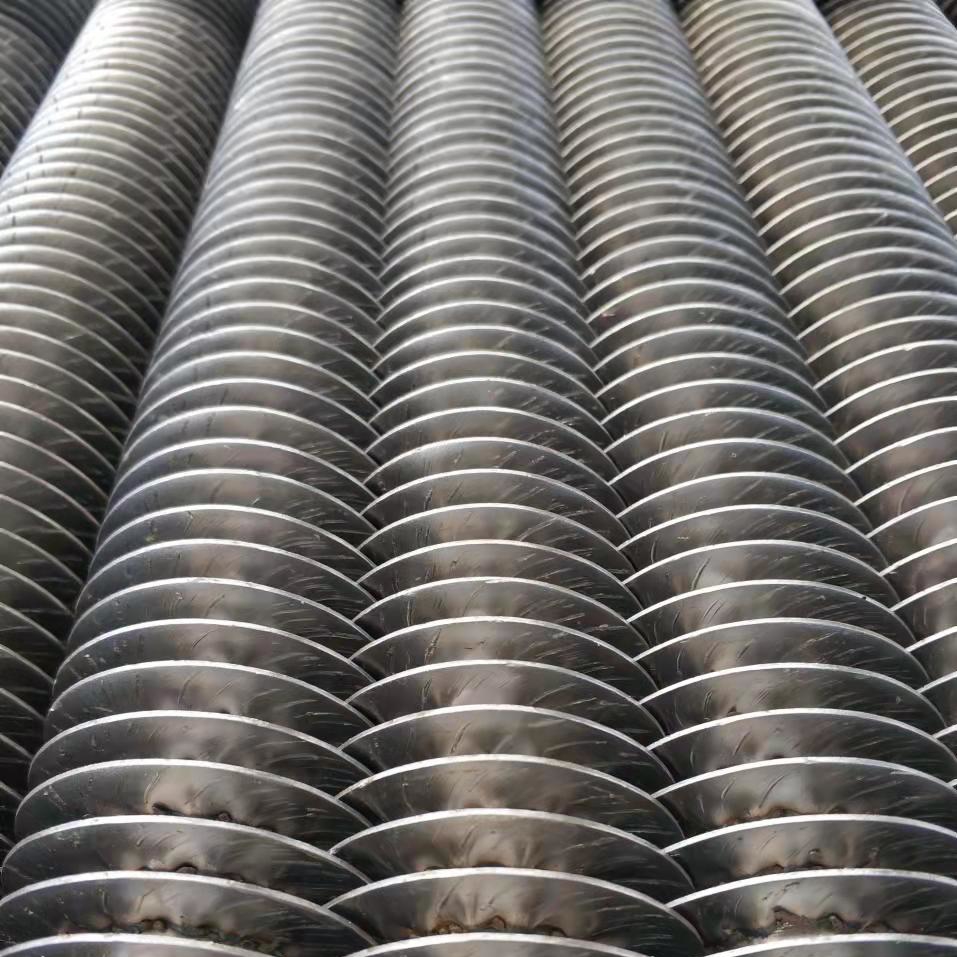

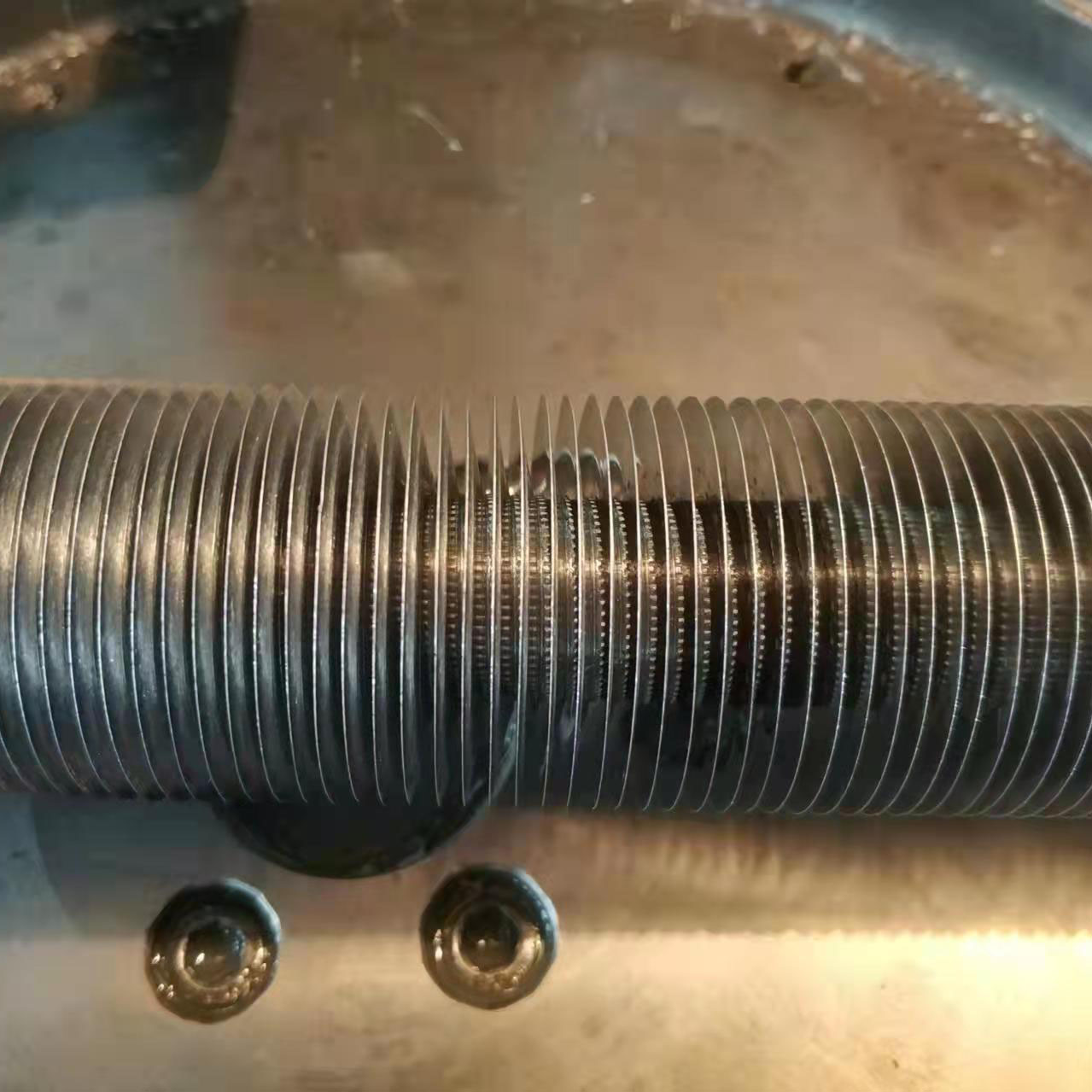

Special Design for Finned Tube Economiser - Laser Welding Finned Tube For Heat Exchanger – Datang

Special Design for Finned Tube Economiser - Laser Welding Finned Tube For Heat Exchanger – Datang Detail:

● Tube outside diameter 8.0–50.0 mm

● Fin outside diameter 17.0 –80.0 mm

● Fin pitch 5 –13 fin/inch

● Fin height 5.0 –17 mm

● Fin thickness 0.4 – 1.0 mm

● Maximum tube lengths 12.0 m

The cold and hot fluid walls are cross-flow heat exchange, and the tube is filled with refrigerant and air outside. The main body of the tube is phase change heat transfer. The tube is generally arranged in a serpentine shape with multiple tubes, and the fins are divided into single, double or multi-row structures.

This kind of heat exchanger is widely used in industrial fields such as petrochemical industry, aviation, vehicles, power machinery, food, deep and low temperature, atomic energy and aerospace. For example, superheaters, economizers, air preheaters, condensers, deaerators, feedwater heaters, cooling towers, etc. in boiler thermal systems; hot blast stoves, air or gas preheaters in metal smelting systems, Waste heat boilers, etc.; evaporators, condensers, regenerators in refrigeration and low-temperature systems; heating and cooling equipment widely used in the petrochemical industry, sugar liquid evaporators and pulp evaporators in the sugar industry and paper industry, These are numerous examples of heat exchanger applications.

Due to the limited reserves of coal, oil, and natural gas resources in the world, and energy shortages, all countries are committed to the development of new energy sources, and actively carry out preheating recovery and energy saving work, so the application of heat exchangers and energy development It is closely related to saving. In this work, the heat exchanger also plays an important role, and its performance directly affects the efficiency of energy utilization. As an effective device for energy utilization and energy conservation, heat exchangers also play an important role in waste heat utilization, nuclear energy utilization, solar energy utilization, and geothermal energy utilization.

1. 99%-100% fully welded, with high thermal conductivity

2. Extremely strong anti-corrosion ability

3. Enhanced structure due to the welding process

4. Flexible as straight tube or bent or coiled heat exchangers

5. Low heat resistance between fins and tube

6. Strong resistance to shock and thermal expansion and contraction

7. Cost and energy saving due to long service life and high exchange rate

The fin tubes are mainly used in heating (gas-fired boilers, condensing boilers, flue gas condensers), in mechanical and automotive engineering (oil coolers, mine coolers, air coolers for diesel engines), in chemical engineering (gas coolers and heater, process cooler), in power plants (air cooler, cooling tower), and in nuclear engineering (uranium enrichment plants).

Product detail pictures:

Related Product Guide:

We now have many fantastic staff members customers superior at advertising, QC, and working with varieties of troublesome problem within the generation system for Special Design for Finned Tube Economiser - Laser Welding Finned Tube For Heat Exchanger – Datang , The product will supply to all over the world, such as: Georgia, Swansea, Croatia, Besides there are also professional production and management , advanced production equipment to assure our quality and delivery time , our company pursues the principle of good faith, high-quality and high-efficiency. We guarantee that our company will try our best to reduce customer purchase cost, shorten the period of purchase, stable products quality, increase customers' satisfaction and achieve win-win situation .

It is a very good, very rare business partners, looking forward to the next more perfect cooperation!