Power plants need to use many condensers to condense the steam emitted by the turbine. In a refrigeration plant, a condenser is used to condense refrigeration vapors such as ammonia and Freon. In the petrochemical industry, condensers are used to condense hydrocarbons and other chemical vapors. The device that converts steam into liquid during the distillation process is also known as a condenser. All condensers operate by taking away the heat of gas or vapor.

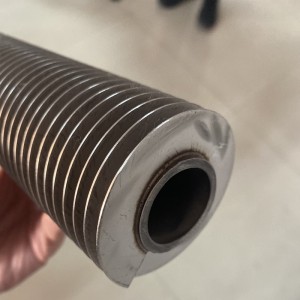

Product use: waste heat recovery application

The condenser is applied in waste heat recovery application systems, on the one hand, due to its advantages of energy conservation, environmental protection, low operating costs, etc., which meet the needs of sustainable economic development strategies of enterprises; On the other hand, it is also in line with the current national policy requirements for environmental protection and energy conservation, which is a major progress in the field of refrigeration and heat exchange.