Popular Design for Fin Tube Radiation - T-Type High Efficient Heat Exchange Finned Tube – Datang

Popular Design for Fin Tube Radiation - T-Type High Efficient Heat Exchange Finned Tube – Datang Detail:

● Bare tube general material: Carbon Steel, Copper, Stainless Steel, Alloy

● Bare tube OD: 10-38mm

● Fin pitch: 0.6-2mm

● Fin height: <1.6mm

● Fin thickness: ~0.3mm

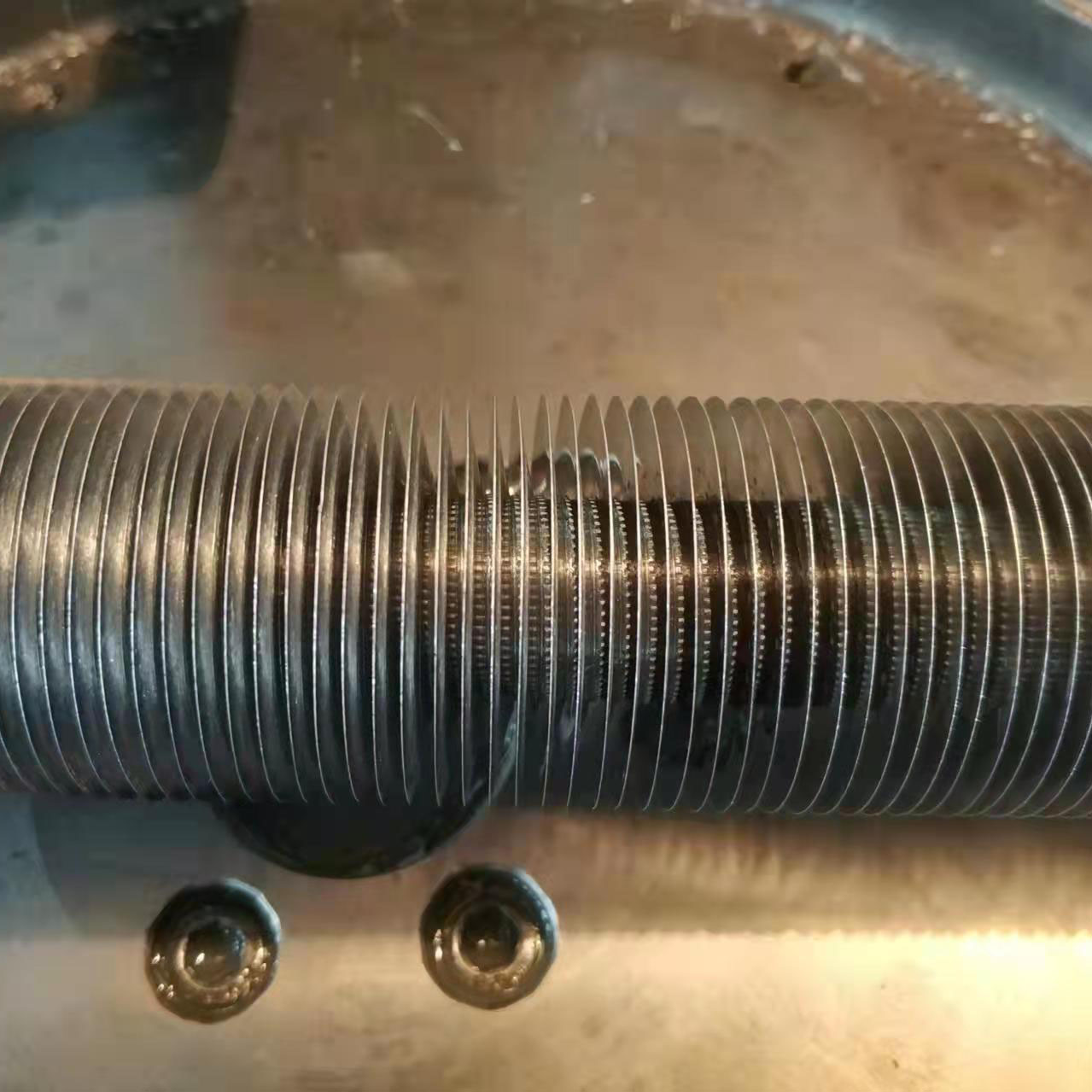

T fin tube is a kind of high efficient heat exchange tube that is made by rolling processing and molding of the light pipe. Its structure characteristic is forming a series of spiral ring T tunnel on the outside the pipe surface.

The medium outside the pipe forms a series of bubbles in the tunnel nuclear when heated. And because the tunnel cavity is in a heated state, the bubble nucleus rapidly expands and increases the inside pressure rapidly by continuously heating, then erupts from a crack in the pipe surface. There is a strong flush power and a certain negative pressure with the bubbles erupting, and which makes the low temperature liquid flow into the T tunnel forming the constant boiling. This way of boiling sends out the heat is much large than the light pipe in an hour and an surface square, so T-type tube has the higher ability of boiling heat transfer.

(1) Good heat transfer effect. The coefficient of heat boiling is 1.6~3.3 times higher than the light tube in the R113 working medium.

(2) Only when the heat medium temperature is higher than the boiling point of cold medium or bubble point is 12℃ to 15℃, the cooling medium can bubbly boils in a regular light tube heat exchanger. Instead, cold medium can be boiling When the temperature is just 2℃ to 4℃ in the t-shaped fin tube heat exchanger. And the bubbling is close, continuous, and rapid. So the T-type tube forms the unique advantages compared with the light pipe.

(3) With CFC 11 for medium single-tube experiment showed that the boiling up heating coefficient of T-type is 10 times of the light pip. For small bundles of liquid ammonia medium experimental results that the total heat transfer coefficient of T-type tube is 2.2 times of the light pipe. The reboiler industrial calibration of C3 and C4 hydrocarbon separation tower shows that , the total heat transfer coefficient of T-type tube is 50% higher than the smooth tube in the low load, and 99% higher in the heavy load.

(4) The pipe price of this kind of porous pipe is cheaper.

(5) It is not easy to scale both within and outside the tube T tunnel slot surface due to the fierce disturbance of internal gas-liquid and seam gas quickly jetting along T high, which ensures the equipment can use for a long time and the heat transfer effect is not affected by scale.

Product detail pictures:

Related Product Guide:

The key to our success is "Good Product Quality, Reasonable Value and Efficient Service" for Popular Design for Fin Tube Radiation - T-Type High Efficient Heat Exchange Finned Tube – Datang , The product will supply to all over the world, such as: Namibia, Guatemala, Iran, Many goods fully conform to the most rigorous of international guidelines and with our first-rate delivery service you will have them delivered at any time and in any place. And because Kayo deals in the entire spectrum of protective equipment, our customers don't have to waste time shopping around.

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.