One of Hottest for Economizer Finned Tubes - G Type Finned Tube(Embedded Finned Tube) – Datang

One of Hottest for Economizer Finned Tubes - G Type Finned Tube(Embedded Finned Tube) – Datang Detail:

Main industries in which the ‘G’ Fin Tubes find service are Process Chemical Plants, Refineries, Gas Processing Plants, Steel Plants, Power Plants, Fertilizer Manufacturing Plants, etc.

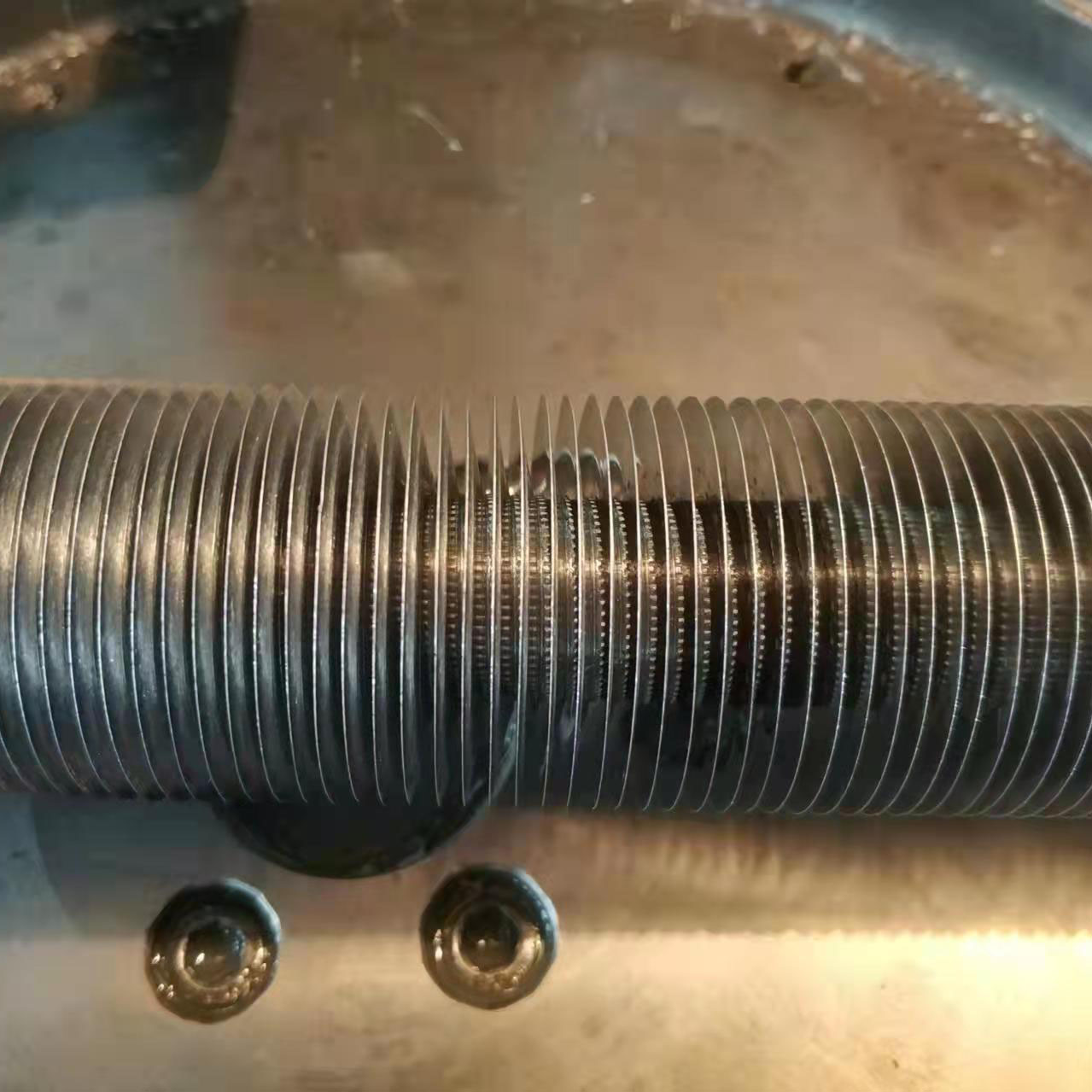

Finned Tube—-G-Type Fintube / Embedded Fintube

A spiraling groove zero.2-0.3 mm (0.008-0.012 in) is plowed into the surface of the base-tube wall such metal is just displaced, not removed. The metal fin is wound automatically into the groove beneath tension, once that the displace metal is rolled back on all sides of the fin to carry it in situ. that’s why this sort is additionally referred to as embedded finned tube. The emotive thickness of the base-tube wall is that the thickness at a lower place the groove. this sort provides wonderful contact, each thermal and mechanical, between fin and groove. though the base-tube metal is exposed to the atmosphere, tests beneath server conditions showed that corrosion over an extended amount is needed before any bond weakness happens.

The G-type fin tube is applicable to warmth up to 750 F degree (450 C degree)

● Fins Per Inch: 5-13 FPI

● Fin Height: 0.25″ to 0.63″

● Fin Material: Cu, Al

● Tube OD: 0.5″ to 3.0″ OD

● Tube Material: Cu, CuNi, Br, Al, SS, CS, Ni, Ti

● Max Process Temperature: 750 °F

★ Oil and gas refineries

★ Petroleum, chemical and organic compound industries

★ Natural gas treatment

★ Steel creating trade

★ Power plants

★ Air acquisition

★ Compressor coolers

High fin stability, wonderful heat transfer, high operative temperature.

The fin/tube wall contact is constant as a result of the setting and makes it attainable to use a wall temperature of up to 450°C.

The fin is ready throughout its length and consequently doesn’t unwind even once partly uprooted.

This kind of finned tube is one amongst optimum selections for having smart effectiveness/cost magnitude relation.

The fin isn’t therefore sturdy to resist mechanical injury once external forces applied on fin space.

Handling shall be through with care to avoid any injury.

Finned tubes is also broken whereas victimisation either steam or aggressive water for cleansing.

As the fins square measure helically wrapped in grouves, un-finned space isn’t lined which may be exposed to corrosive media and galvanic corrosion at the bottom of the fins may be accumulated.

Tube shall be straight with disembarrass facet space to create a decent finned tube.

It is onerous to use core tube once more once finning is unsuccessful.

Fins ought to be mounted at each ends avoiding un-wrapping.

Product detail pictures:

Related Product Guide:

We are proud of the superior customer gratification and wide acceptance due to our persistent pursuit of top of the range both of those on merchandise and service for One of Hottest for Economizer Finned Tubes - G Type Finned Tube(Embedded Finned Tube) – Datang , The product will supply to all over the world, such as: Portland, Botswana, Indonesia, All of our products comply with international quality standards and are greatly appreciated in a variety of markets around the world. If you are interested in any of our products or would like to discuss a custom order, please feel free to contact us. We are looking forward to forming successful business relationships with new clients in the near future.

The customer service staff is very patient and has a positive and progressive attitude to our interest, so that we can have a comprehensive understanding of the product and finally we reached an agreement, thanks!