Special Design for Helical Tube Bending - Sprial Welding Finned Tube(Helical Finned Tubes) – Datang

Special Design for Helical Tube Bending - Sprial Welding Finned Tube(Helical Finned Tubes) – Datang Detail:

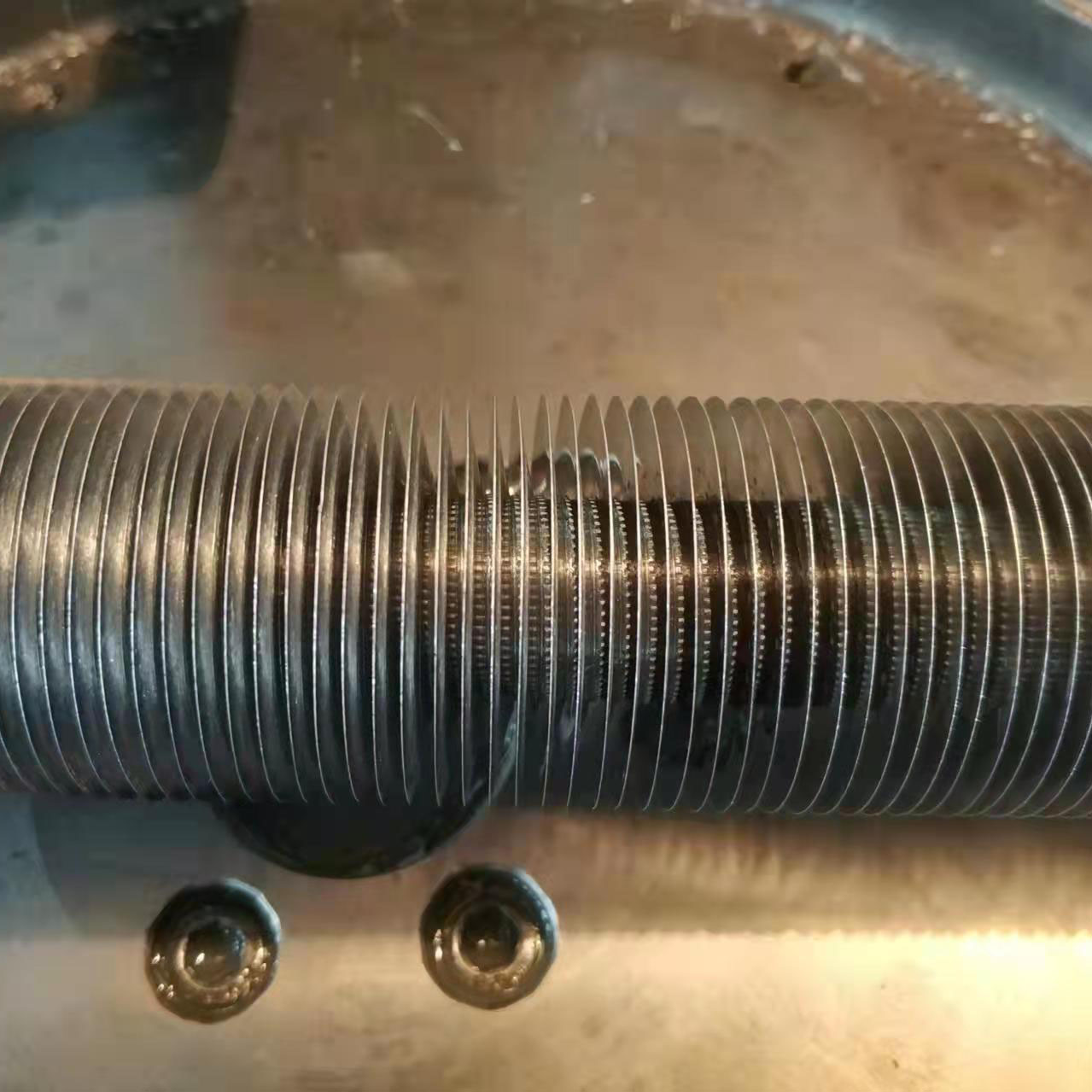

Helical Finned Tubes provide the designer with high thermal efficiency and compact design solutions for a whole range of heat exchangers where clean flue gases are encountered. Helical finned Tubes are manufactured in both Solid and Serrated win profiles.

Helical Solid Finned Tubes are produced by helically wrapping continuous fin strip tube. The fin strip is wounded spirally onto the tube and welded continuously with a High Frequency Electrical process to the tube along the spiral root. The fin strip is held under tension and confined laterally as it is formed around the tube, thereby ensuring that the strip is in forceful contact with the tube surface. A continuous weld is applied at the point where the fin strip first begins to bend around the tube diameter, using the gas metal arc welding process.

For a given pipe or tube size, the desired heat transfer surface area per unit length of tube can be obtained by specifying the appropriate fin height and/or number of fins per inch of length.

This welded steel finned tube configuration can be used for practically any heat transfer application, and is particularly suited to high temperature, high pressure applications. The important features of this configuration are efficient, effective bond of fin to tube under all conditions of temperature and pressure, and ability to withstand high fin-side temperatures.

A continuous helical fin is attached to the base tube by high frequency electric resistance welding in order to give an efficient and thermally reliable bond.

|

Base Tube O.D |

Base Tube Thickness (mm) |

Fin Height |

Fin Thickness(mm) |

Fin Pitch(mm) |

|

22 mm ~219 mm |

2.0 mm ~16 mm |

8 mm ~ 30 mm |

0.8 mm ~ 4.0 mm |

2.8 mm ~ 20 mm |

|

Base Tube Material |

Fin Material |

Tube Length (Mtr) |

||

|

Carbon Steel, Alloy Steel, Stainless Steel and Corrosion-resistance Steel |

Carbon Steel, Alloy Steel, Stainless Steel and Corrosion-resistance Steel |

≤ 25Mtrs |

||

Product detail pictures:

Related Product Guide:

abide by the contract", conforms into the market requirement, joins in the market competition by its good quality also as provides a lot more comprehensive and great company for purchasers to let them turn into huge winner. The pursue from the firm, would be the clients' gratification for Special Design for Helical Tube Bending - Sprial Welding Finned Tube(Helical Finned Tubes) – Datang , The product will supply to all over the world, such as: Guatemala, Macedonia, India, Providing Quality Products, Excellent Service, Competitive Prices and Prompt Delivery. Our products are selling well both in domestic and foreign markets. Our company is trying to be one important suppliers in China.

Timely delivery, strict implementation of the contract provisions of the goods, encountered special circumstances, but also actively cooperate, a trustworthy company!