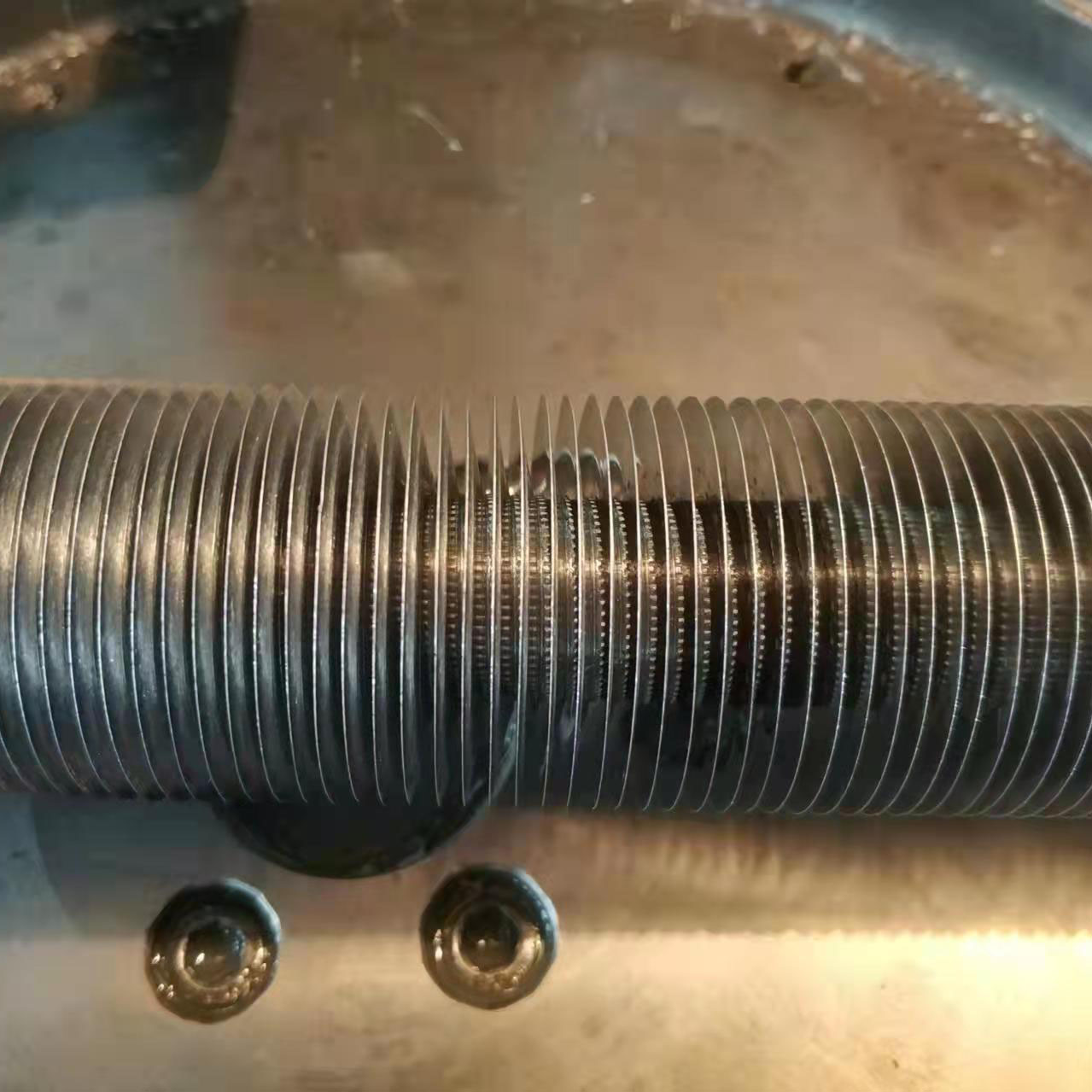

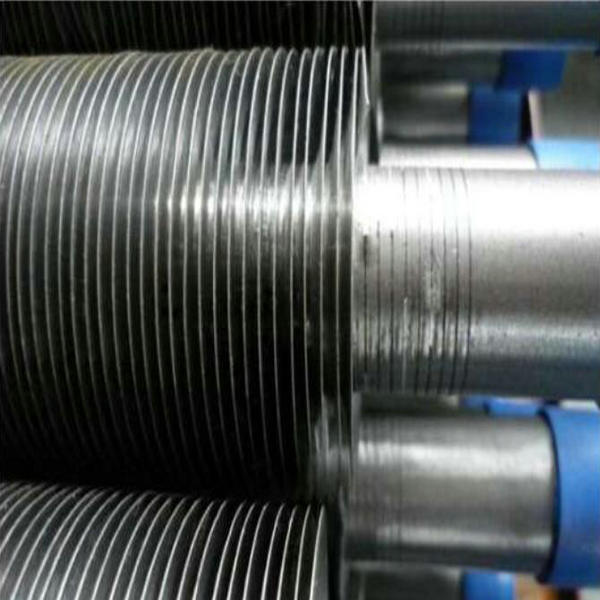

OEM Customized Drying Finned Tube - G Type Embedded Spiral Finned Tube – Datang

OEM Customized Drying Finned Tube - G Type Embedded Spiral Finned Tube – Datang Detail:

● Bare tube general material: Copper, Alloy, Carbon Steel, Stainless Steel

● Bare tube OD: 16-63mm

● Fin general material: Aluminum

● Fin pitch: 2.1-5.0mm

● Fin height: <17mm

● Fin thickness: ~0.4mm

G type embedded spiral finned tube is processed from a certain width in the steel pipe and spiral groove depth, then inlays the ribbon on the steel pipe by the equipment. In winding process, as the pre-tightening force to a certain extent so the strip will be firmly in the spiral groove, to ensure there is a certain contact area between steel band and steel pipe. In order to prevent the strip spring falling off the light tube, the two ends of the steel strip need to weld onto the steel pipe. In order to set easily, there should be a certain clearance between steel belt and spiral groove. If the clearance is too small the setting process will be difficult to proceed smoothly. In addition, the steel belt of winding there will always be a certain amount of rebound, which makes it cannot very good joint among the steel belt and spiral groove bottom. Inlaid fins can be conducted on general equipment, and they cost little. Mcelroy companies in the United States the company I used the advanced production equipment, slotting embedding technology is advanced, from stable, embedded and firm, pulled off force not less than 70 n, the allowable temperature can reach 400 ℃, has the strong ability of temperature resistance and thermal shock, widely used in petrochemical air cooler.

Product detail pictures:

Related Product Guide:

Excellent 1st,and Client Supreme is our guideline to deliver the ideal provider to our prospects.Nowadays, we have been seeking our best to become certainly one of the most effective exporters in our discipline to meet shoppers more require for OEM Customized Drying Finned Tube - G Type Embedded Spiral Finned Tube – Datang , The product will supply to all over the world, such as: Malta, Bandung, Peru, Abiding by our motto of "Hold well the quality and services, Customers Satisfaction", So we give our clients with high quality products and solutions and excellent service. Be sure to feel free to contact us for further information.

Superb technology, perfect after-sales service and efficient work efficiency, we think this is our best choice.