Laser Welded Finned Tube Machine

Laser welded finned tube machine,High-Efficiency, High-Intensity Laser Fin Tube Welding Equipment.This is an efficient and precise welding method that utilizes a high-energy-density laser beam as the heat source. It is capable of welding various materials, including stainless steel, copper, and carbon steel. The equipment offers numerous advantages, such as uniform welding, aesthetically pleasing weld seams, non-contact operation, deep penetration, minimal deformation, energy efficiency, and ease of welding thin materials.Incorporating advanced design concepts and an intuitive operation mode, this system enables high-quality welding of fin tubes made from multiple materials.

MATERIAL COMBINATIONS_____

TUBE ____STRIP___

Stainless Steel Stainless Steel

Stainless Steel Carbon Steel

Stainless Steel Copper

Carbon Steel Carbon Steel

Carbon Steel Stainless Steel

Cu-Ni-Alloy Cu-Ni-Alloy

Cu-Ni-Alloy Copper

Titanium Titanium

Titanium Copper

Advantages of Our Laser Welded Finned Tube Machine

1. Solves the limitations of traditional high

frequency welding, enabling welding of copper, alloy, stainless steel, and more.

2. Localized heating with minimal energy consumption and ultra-low power usage.

3. Intuitive operation based on high-frequency welding templates, suitable for operators of all skill levels.

4. Non-contact process, no electrodes required, zero high-frequency radiation, and no need for radiation shielding.

5. Dual control via touchscreen and mechanical buttons for redundant reliability.

6. Automatic laser power adjustment based on speed, ensuring smooth welding even for thinwalled materials.

7. Segmented welding capability with up to 8 customizable segments (spacing, length, power

8. Robotic arm-controlled welding position with

0.01mm precision.

9. Stores process parameters for 9 tube diameters for quick switching.

10. User-friendly touchscreen interface with animated status displays.

11. Servo-controlled cart ensures uniform spacing, stable operation, and long lifespan.

12. Comprehensive alarm system for easy troubleshooting.

13. Energy-efficient compared to traditional copper lamps, gold needles, and hydraulic systems.

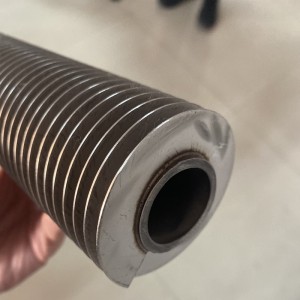

Spiral finned tubes produced using DATANG laser welding equipment

Evaluation of the Actual Effect of Laser Welding Spiral Finned Tube Equipment:

1. Highly Energy-Efficient: Saves more than 10 times the electricity compared to high-frequency welding models, maintenance-free.

2. Latest Design (Internationally Synchronized): Utilizes a solid-state flow method, where steel strip is 3D cold-extruded and rolled into three-dimensional finned rings within a double mold, resulting in a bright, wrinkle-free surface.

3. Compared to other finned tubes, it offers greater corrosion resistance, higher heat exchange efficiency, and a longer service life under the same material conditions.

4. Minimal Changes in Metallographic Structure, with Uniform and Consistent Welds.

5. High Bond Strength: 100% full weld coverage, with weld strength exceeding that of the base material.

Customization Instructions for Complete Spiral Finned Tube Production Line Equipment:

1. Customers need to provide the specifications and material of the base tube, the specifications and material of the steel strip, and the required operating environment for the finned tubes.

2. The power and stroke selection should be based on the customer’s required production efficiency and cost-effectivenes

Customer use case